Conveyor Efficient Metal Detector For Coal - Dongguan COSO Electronic Technology Co., Ltd.

- Description details

-

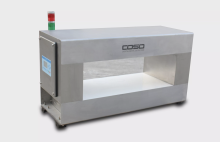

Online Metal Detector

SEC Series Metal Detector

SEC series digital intelligent online metal detector can eliminate signal interference furthest from products themselves (like ore, coal, chemical, renewable resources, waste etc.) and conveyor belt itself by using DSP digital intelligent technology, at the same time, ensuring conveyor and products (like ore, coal, chemical, renewable resources, waste etc.) to pass detector, also can achieve perfect detection results.

Application: Plastic, building material, wood, paper making, coal, textile, mines, cement, thermal power, chemical, chemical, waste processing and renewable resources industry etc. it is used for detecting bulk metallic impurities left or mixed with products, which can help avoid damage to working machines.

Features:

1. Using DSP digital intelligent technology deals with detection signal and interference signal, also can effectively and automatically control interference effects, possessing high detection sensitivity and strong anti-interference ability.

2. Having function of self-learning and memory, metal detector can automatically learn and memory products’ features; effectively eliminate “metal effect” that ore, coal itself possesses, besides, it can memory products’ parameters up to 100 kinds.

3. Adjustment of products’ parameter is highly digital and easy to operate. By one-bottom self-learning can precisely set parameters automatically, no need for human to adjust and avoid complex debugging.

4. Metal detector has dialogue type LCD screen, menu, thin film switch bottom; convenient for operation.

5. Metal detector is waterproof, anti-vibration and has strong adaptability to environment and temperature changes.

6. The conveyor belt generally will be installed horizontally, but it can be applied to different angle according to your request.

7. The detector head can be separated, but the belt do not need to be cut.

8. When the impurities is detected,the metal detector will send the stopping signal from the intermediate relays to the conveyor belt system.

Specification

1.Structure:

2.Technical Parameter

Name

Parameter

Detecting Height

200mm (over 200mm, can be customized)

Detecting Width

500mm (over 500mm, can be customized)

Sensitivity

Decided by the width and height of tunnel, refer to below sheet

Power Supply

AC220V±10%,50-60HZ

Voltage

120W

Alarm

Release alarm signal to controller or automatic reject system or stop with alarm

Working Environment

-20℃~50℃;Humidity below90%

Notes:

1. All the sensitivity parameters above is on the basis of the test card detected on conveyor belt; while the actual sensitivity will be affected by the product’s features and working environment.

2. Above technical parameters are some ordinary models, if you want to know more different technical parameters, please consult our employees.

3. Products will constantly upgrade; please refer to our newest technical parameters for changes on parameters.

- About us

-

Who is COSO?

COSO Electronic Tech has been established since 2005 and has more than 15 years experience in the metal detector field in Dongguan, China. With years of development, COSO covering an area of 10, 000 square meters, is located at Yuwu village, Dongguan, and has its own engineering team, very strong after-service team. COSO has dedicated in product sensitivity, stability and innovation in food industrial, shoes, clothes, plastic industrial, pharmaceutical etc. All of the machines are with one year guarantee.

Our service products includes as metal detector, check weigher, metal separator and security inspection equipment. Our products have taken large market shares in domestic as well as overseas markets such as Southeast Asia, Europe and America, Africa and so on.

— ABOUT US

Our company has been adhered to the enterprise idea of "Continuously Pursue Excellent Quality; Constantly Focus on Technology Innovation; Consistently Adhere to Quality Service". With our diligence, wisdom and persistence, we always work to improve the professionalism and reliability of the product. We pursue to supply customers with effective solutions and quality services. We would like to invite you come and grow with us together.

Our mission

Make production more efficient and make products more assured.

Our vision

To become a globally trusted manufacturer of testing equipment.

Our values

Integrity, responsibility, extreme, innovation, gratitude, and win-win.